Rack-Supported Mezzanines in Portland, Oregon

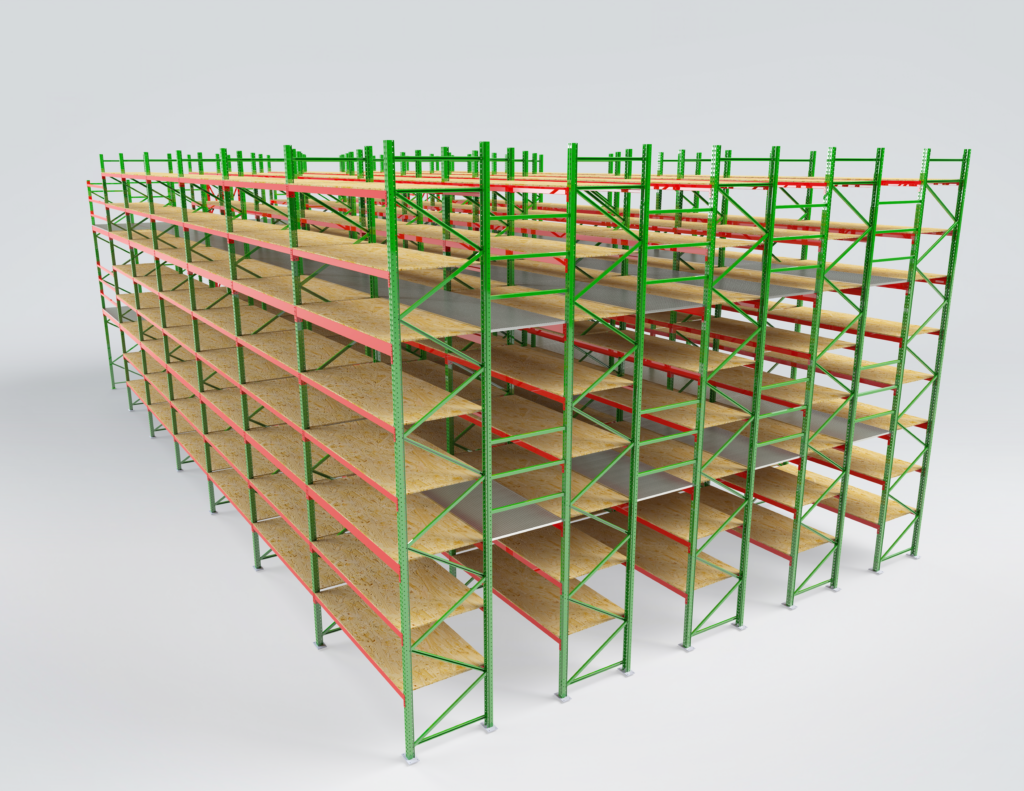

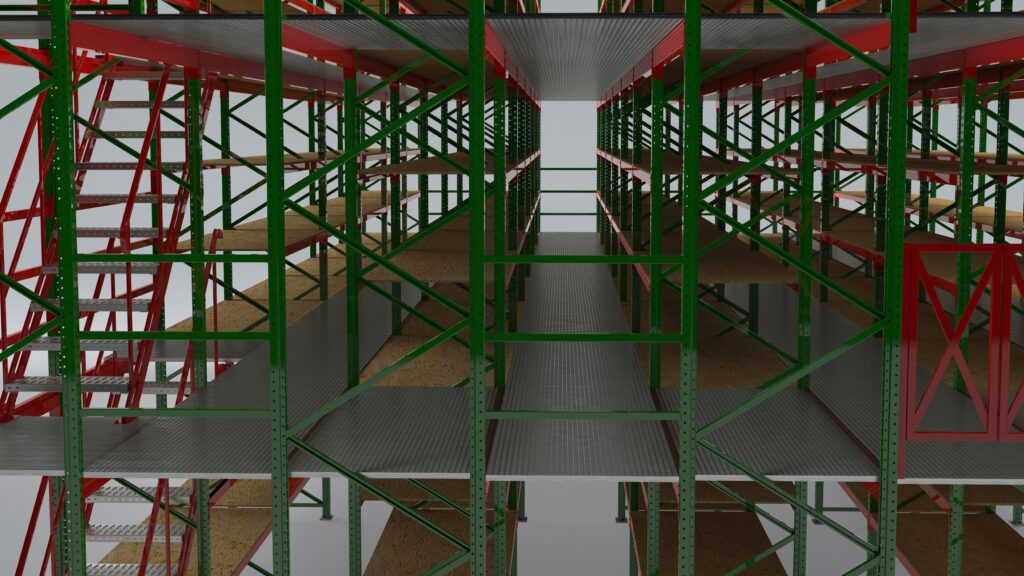

Rack-supported mezzanines expand your warehouse capacity by adding an extra floor level using reinforced pallet rack components. These systems maximize vertical space while maintaining wide aisles and safe working areas.

At Lenokers, we design and install mezzanines for warehouses across the Portland metropolitan area and throughout Oregon.

Types of Rack-Supported Mezzanines

Standard Rack-Supported Mezzanines

Built with vertical frames and pallet rack traverses.

Provide shelves of large sizes and wide aisles for storage and operations.

Hybrid Mezzanines

Ground floor for pallet storage.

Upper levels are used for crates, unit loads, or office space.

Flexible configurations for material handling or workspace needs.

Customized Solutions

Designed to meet load-bearing requirements.

Supports decking, pallet gates, handrails, and catwalks.

Fire-resistant decking ensures airflow and safety compliance.

Benefits of Rack-Supported Mezzanines

Expand warehouse space vertically, up to several levels.

Increase throughput with multiple loading/unloading points.

Reduce downtime by enabling simultaneous workstations.

Integrate with material handling equipment for better workflow.

Cost-effective compared to building expansion or relocation.

Custom-engineered to fit your warehouse and OSHA standards.

Why Work With Lenokers?

Lenokers has decades of experience installing and dismantling mezzanine systems worldwide. With strong expertise in Oregon warehouse projects, we understand how to maximize your storage potential while keeping your facility compliant and efficient.

📞 Contact us today — we’ll make sure you get the right mezzanine system, tailored to your requirements.