In modern logistics and supply chain management, the ability to store and access goods efficiently directly impacts profitability. For businesses seeking to maximize operational efficiency, choosing the right warehouse racking system is a critical decision. This article provides a detailed cost-benefit analysis of the most common types of industrial warehouse racking systems, helping warehouse operators and decision-makers invest wisely.

Understanding Warehouse Racking Solutions

Warehouse racking solutions are engineered storage systems that maximize vertical and horizontal space within a warehouse. They come in various designs, each tailored for specific product types, storage density needs, and retrieval frequency. Selecting the appropriate racking configuration can enhance warehouse flow, safety, and scalability while reducing labor and space costs.

Cost Factors in Racking Systems

When evaluating racking systems, it’s essential to consider both direct and indirect costs:

- Initial investment (materials, design, installation)

- Maintenance and operational costs

- Space utilization efficiency

- Adaptability and scalability

- Compliance with safety and load-bearing standards

Now, let’s compare the most common warehouse racking systems in terms of cost-effectiveness.

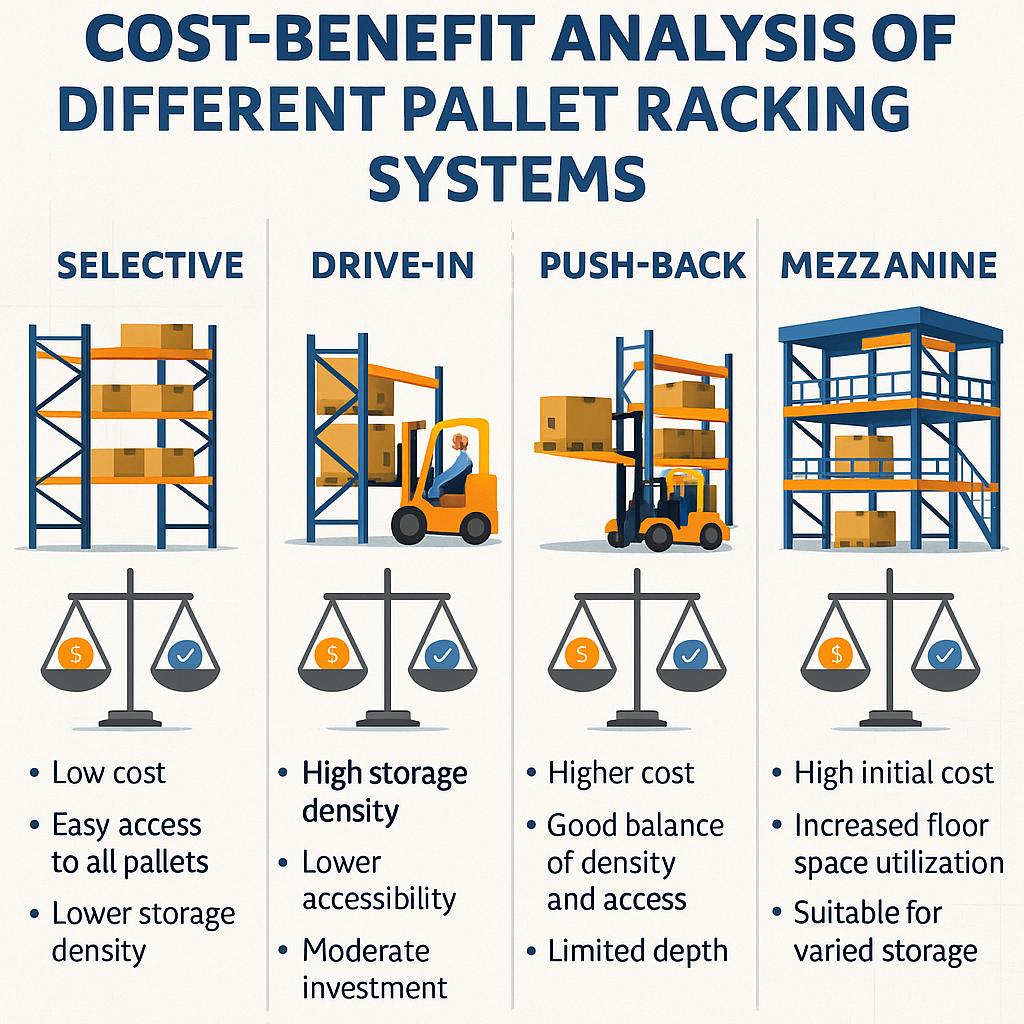

1. Selective Pallet Racking

Cost: Low to Moderate

Benefits:

- Most common and affordable option

- Easy access to every pallet

- Compatible with standard forklifts

Drawbacks:

- Lower storage density

- Not ideal for high-volume bulk storage

Best for: Warehouses with a high variety of SKUs and moderate inventory turnover.

2. Drive-In/Drive-Thru Racking

Cost: Moderate to High

Benefits:

- High-density storage

- Maximizes cubic space by eliminating aisles

- Ideal for bulk goods and LIFO/FIFO systems

Drawbacks:

- Limited access to individual pallets

- Higher risk of forklift damage

Best for: Industrial facilities storing large volumes of uniform products.

3. Push Back Racking

Cost: Moderate to High

Benefits:

- Multiple pallets per lane

- High selectivity with better space efficiency than drive-in

- Reduced retrieval time

Drawbacks:

- Higher initial cost

- Not suitable for fragile or unstable goods

Best for: Warehouses with medium SKU counts and moderate-to-high turnover.

4. Pallet Flow (Gravity Flow) Racking

Cost: High

Benefits:

- Supports FIFO inventory management

- Excellent space and labor efficiency

- Automated movement using gravity rollers

Drawbacks:

- Expensive to install and maintain

- Requires uniform pallet quality

Best for: Perishable goods or date-sensitive inventory.

5. Cantilever Racking

Cost: Moderate

Benefits:

- Ideal for long, bulky items (e.g., pipes, lumber)

- Easily adjustable arms for varied product sizes

Drawbacks:

- Not suitable for palletized goods

Best for: Manufacturing and construction storage environments.

6. Warehouse Racking Mezzanine Systems

Cost: High (but scalable)

Benefits:

- Doubles usable floor space without building expansion

- Integrates with other industrial warehouse racking systems

- Customizable for offices, storage, or picking zones

Drawbacks:

- Requires structural assessments and higher installation costs

Best for: Facilities needing both storage and operational space within limited footprints.

Working with Warehouse Racking Companies: ROI Considerations

Choosing the right provider is as important as selecting the racking system itself. Reputable warehouse racking companies like Lenokers offer:

- Site-specific design consultations

- Compliance with EU standards and safety norms

- Scalable, future-proof warehouse racking solutions

- Experienced installation teams and support

While higher-end systems such as warehouse racking mezzanine installations require more upfront investment, they offer superior long-term returns via space maximization and workflow efficiency.

Final Thoughts: Investing Smart in Racking Infrastructure

Every warehouse has unique needs. A strategic approach, guided by expert assessment and clear cost-benefit analysis, leads to smarter investment and long-term gains. When you align your operations with the right warehouse racking solution, you’re not just storing goods — you’re building productivity.

Contact Lenokers for a Custom Warehouse Racking Solution

At Lenokers, we specialize in planning, delivering, and installing high-performance warehouse racking systems tailored to your operational goals. From selective racks to warehouse racking mezzanine structures, we help businesses increase efficiency, safety, and scalability.

Reach out today to speak with our B2B team and explore a smarter way to store.